Precision Heating Solutions: Cartridge Heater with Thermocouple and Band Heater with Thermocouple

In today's rapidly evolving industrial landscape, precision and efficiency in heating systems are more crucial than ever. Industries ranging from plastic manufacturing to food processing and packaging rely on reliable and high-performance heating solutions to ensure consistent production quality. Two of the most widely used heating solutions in industrial applications are the cartridge heater with thermocouple and the band heater with thermocouple. These advanced devices provide accurate temperature control, energy efficiency, and robust performance under challenging conditions.

This blog explores the features, applications, and advantages of these heaters and explains why they have become integral to modern industrial operations.

Understanding Cartridge Heaters with Thermocouples

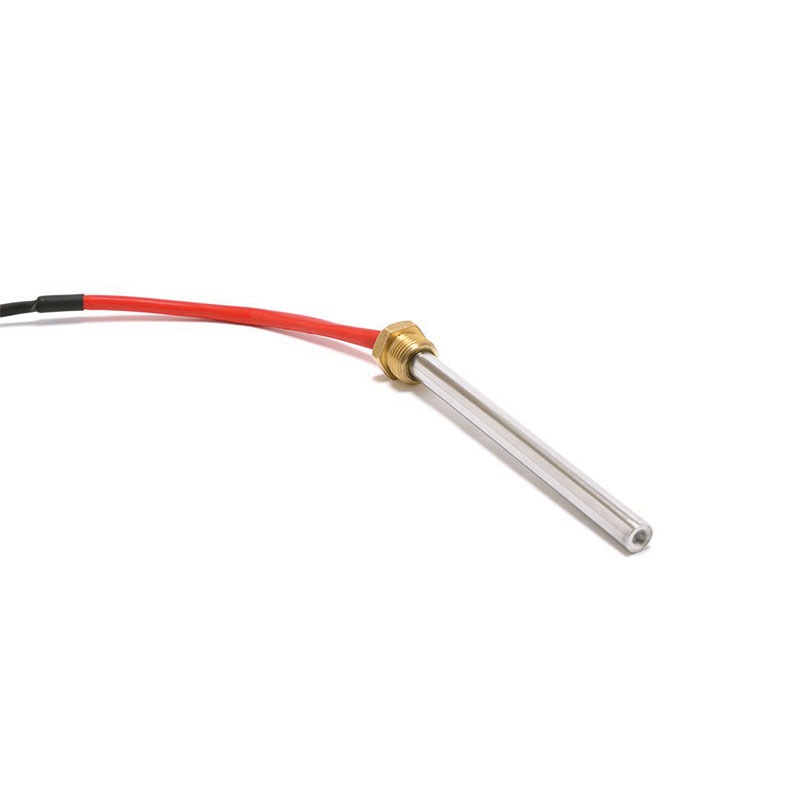

A cartridge heater with thermocouple is a cylindrical heating element that is inserted into holes in metal blocks or components. It is designed to deliver localized, high-temperature heating in a compact form factor. What sets this heater apart is the built-in thermocouple — a temperature sensor that allows for precise control of the heating element’s temperature.

Key Features:

-

High Watt Density: Cartridge heaters are known for their ability to deliver high levels of heat in small spaces.

-

Integrated Thermocouple: The thermocouple enables real-time monitoring and feedback for optimal temperature regulation.

-

Durability: Constructed with stainless steel and high-grade insulation, these heaters offer longevity and resistance to wear and tear.

-

Fast Heating Response: Cartridge heaters heat up rapidly, which helps in improving overall productivity.

Applications:

-

Injection molding and plastic extrusion

-

Packaging equipment

-

Die heating

-

Medical devices

-

Food processing machinery

The integration of a thermocouple eliminates the need for external sensors, reducing installation complexity and improving thermal efficiency.

Exploring Band Heaters with Thermocouples

A band heater with thermocouple is designed to wrap around cylindrical surfaces such as barrels, nozzles, or pipes to deliver uniform surface heating. These heaters are commonly used in applications where consistent surface temperature is essential.

Key Features:

-

Uniform Heat Distribution: Band heaters provide even heat across the surface area, avoiding hotspots.

-

Built-in Thermocouple: Like cartridge heaters, these band heaters incorporate thermocouples for better temperature regulation.

-

Customizable Designs: They can be tailored to specific sizes, wattages, and voltages.

-

Rugged Build: Most band heaters are made from stainless steel or mica insulation, providing high performance and reliability.

Applications:

-

Plastic processing equipment

-

Extruder barrels

-

Drum heating

-

Food and beverage production

-

Pharmaceutical industry

The inclusion of thermocouples ensures that heating is always maintained within safe and optimal limits, preventing damage to sensitive machinery and materials.

Why Thermocouple Integration Matters

Whether in a cartridge heater with thermocouple or a band heater with thermocouple, the inclusion of a thermocouple provides several distinct advantages:

1. Accurate Temperature Monitoring

Thermocouples deliver real-time temperature readings, ensuring that the heater operates at the correct temperature and avoids overheating.

2. Enhanced Safety

Temperature regulation minimizes the risk of fire, equipment damage, and production defects — essential for industries where precision matters.

3. Process Efficiency

Better control means less energy wasted, leading to more efficient operations and reduced energy bills.

4. Integration with Control Systems

Most industrial automation systems can easily integrate with heaters that have built-in thermocouples, simplifying monitoring and control.

Choosing Between Cartridge and Band Heaters with Thermocouples

When selecting the right heating solution, understanding the differences between cartridge and band heaters is essential:

| Feature | Cartridge Heater with Thermocouple | Band Heater with Thermocouple |

|---|---|---|

| Shape | Cylindrical rod | Wrap-around band |

| Installation | Inserted into drilled holes | Clamped onto cylindrical surfaces |

| Heating Style | Internal heating | Surface heating |

| Common Uses | Dies, molds, small metal blocks | Barrels, pipes, containers |

| Heat Transfer | Conductive | Conductive & radiant |

Your choice will depend on your specific industrial need — whether you need internal point heating or surface coverage.

Maintenance and Best Practices

To maximize the lifespan and efficiency of your cartridge heater with thermocouple or band heater with thermocouple, follow these maintenance tips:

-

Ensure proper fitment to avoid heat loss.

-

Regularly inspect wiring and insulation for wear or corrosion.

-

Avoid overheating by using appropriate controllers and monitoring systems.

-

Clean surfaces regularly to prevent buildup that could impair heat transfer.

Conclusion

In industries where precision and consistency are non-negotiable, choosing the right heating element can significantly impact productivity and product quality. Both the cartridge heater with thermocouple and band heater with thermocouple offer reliable, efficient, and customizable heating solutions designed for the demands of modern manufacturing.

By integrating thermocouples directly into the heaters, businesses benefit from improved safety, better control, and more streamlined operations. Whether you're working with metal molds or plastic extrusion machines, investing in these advanced heating technologies is a smart move toward efficient and sustainable production.

Looking for high-quality industrial heaters? Connect with reliable manufacturers and suppliers who specialize in customized cartridge heaters with thermocouples and band heaters with thermocouples tailored to your application.

Comments

Post a Comment